Direct to Fabric (DTF) transfer printing is a cutting-edge technique offering vibrant, long-lasting personalized designs on diverse fabrics. This method combines artistic vision and technical precision, allowing for intricate patterns on single transfer sheets with cost-efficiency and versatility. DTF Printing empowers brands, artists, and enthusiasts to create unique items from clothing to home decor, streamlining production, saving time, reducing waste, and enhancing customer satisfaction while fostering stronger connections. Best practices include strategic layout optimization, using top-tier materials, and meticulous preparation for high-quality prints, making DTF a game-changer in textile printing.

“Revolutionize your DIY projects with the power of personalized DTF (Direct to Fabric) transfer sheets! This innovative technique allows for the arrangement of multiple designs on a single sheet, unlocking endless creative possibilities. In this comprehensive guide, we’ll explore the benefits and techniques behind creating multifaceted designs using DTF Transfer. From understanding the process to optimizing layouts and ensuring high-quality prints, discover how to master this art, opening up a world of unique applications.”

- Understanding DTF Transfer: A Brief Overview

- The Benefits of Personalized Design Arrangements

- Creating Multifaceted Designs: Techniques and Tools

- Optimizing Layouts for Efficient DTF Printing

- Best Practices for Achieving High-Quality DTF Prints

- Real-World Applications and Creative Possibilities

Understanding DTF Transfer: A Brief Overview

Understanding DTF Transfer: A Brief Overview

DTF (Direct to Fabric) transfer printing is a cutting-edge technique that allows for the creation of personalized, intricate designs on various fabrics and materials. This method involves transferring high-quality prints directly onto fabric using a heat press, ensuring vibrant colors and long-lasting durability. DTF offers unparalleled versatility, enabling users to easily incorporate multiple design elements into a single transfer sheet. Each design can be precisely arranged, allowing for creative freedom in personalizing products ranging from apparel to home decor items.

With DTF Printing, the process starts by designing or selecting artwork using specialized software. These designs are then separated and positioned on a transfer sheet, often in a grid format. This sheet is carefully heated before being pressed against the fabric, transferring the ink and creating a crisp, detailed print. The result is a unique, customized product that showcases stunning DTF prints.

The Benefits of Personalized Design Arrangements

In today’s competitive market, personalized design arrangements offer a unique advantage for businesses and creatives alike. By utilizing DTF (Direct to Fabric) Transfer technology, designers can create intricate and diverse patterns on a single transfer sheet. This method allows for not only cost-efficiency but also remarkable versatility in product customization. Imagine the possibilities of combining multiple designs into one cohesive layout; from clothing lines featuring unique artistic elements to home décor items with personalized messages, DTF Printing enables endless creative expression.

Moreover, this innovative approach streamlines production processes. With a single transfer sheet, businesses can produce a variety of products without the need for separate printing runs for each design. This not only saves time but also reduces waste, making it an eco-friendly option. Personalized DTF Transfers empower brands and artists to offer tailored experiences to their customers, fostering stronger connections and enhancing customer satisfaction.

Creating Multifaceted Designs: Techniques and Tools

Creating Multifaceted Designs with DTF Transfer Sheets involves a blend of artistic vision and technical precision. Designers can craft intricate patterns by combining multiple designs on a single transfer sheet, enabling the production of unique and personalized items. This technique leverages DTF (Direct to Fabric) Printing technology, which allows for high-quality, precise application of designs directly onto various materials.

Specialized tools such as vector graphic software and laser cutters play a pivotal role in this process. Designers first create or source design elements that complement each other aesthetically. Using vector graphics ensures clean lines and scalable images, crucial for achieving crisp DTF prints. These designs are then meticulously arranged, considering factors like color coordination, scale, and spatial harmony. After finalization, the composite design is exported as a cutting file, ready to be etched onto the DTF transfer sheet using a laser cutter.

Optimizing Layouts for Efficient DTF Printing

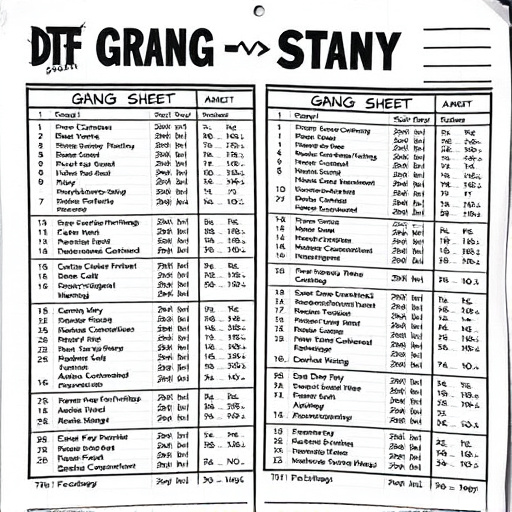

In the realm of DTF (Direct to Fabric) printing, optimizing layouts on a single transfer sheet is key to achieving efficient and high-quality prints. By carefully arranging multiple design elements, print shops can maximize fabric utilization while minimizing waste. This process involves strategic placement of each DTF transfer, considering factors like design size, complexity, and the type of fabric being printed. A well-optimized layout ensures that each design element receives adequate exposure to the fabric during the printing process, resulting in crisp, vibrant DTF prints.

To enhance efficiency, designers should aim for a balanced distribution of designs across the transfer sheet. Smaller, simpler motifs can be placed closer to the edges, leaving ample space for larger, more intricate patterns in the center. This approach not only prevents overlapping but also allows for better control over print registration. Additionally, utilizing software tools that simulate the printing process can aid in visualizing how the final layout will translate onto the fabric, making adjustments before cutting the transfer sheet.

Best Practices for Achieving High-Quality DTF Prints

Achieving high-quality DTF (Direct to Fabric) prints requires a combination of precise techniques and best practices. First, use top-quality materials, including premium transfer sheets and inks designed specifically for DTF printing. These products ensure better adhesion and vibrant colors on various fabrics. Additionally, preparing your design files correctly is paramount; vector graphics with clean lines and proper resolution (300 DPI or higher) are ideal for crisp prints.

Before printing, carefully pre-press the transfer sheet to secure it to the fabric. This step eliminates air bubbles and ensures even ink transfer. When printing, maintain consistent settings across jobs to preserve consistency in your DTF prints. Regularly cleaning and maintaining your printer is also vital; remove any buildup or residual ink to prevent print quality degradation. Lastly, allow sufficient drying time for inks to set properly, preventing smudging or transferring during handling.

Real-World Applications and Creative Possibilities

The personalized arrangement of multiple designs on a single transfer sheet opens up a world of real-world applications and creative possibilities. This innovative technique, often facilitated by DTF (Direct to Fabric) Transfer technology, allows for the efficient production of unique, customized textiles. From fashion and apparel to home decor and promotional merchandise, DTF Printing offers an unparalleled level of versatility. Designers can now seamlessly integrate diverse patterns, logos, and graphics onto various fabrics without the need for complex set-up processes or specialized equipment.

This method has democratized creative expression, empowering both professionals and hobbyists alike to bring their visions to life. With DTF Transfer, creating limited-edition clothing lines, personalized gifts, or even small-batch art pieces becomes more accessible. The ability to quickly adapt designs and cater to individual preferences makes this technology a game-changer in the fields of print on demand and custom apparel. Furthermore, DTF Prints’ potential extends into cultural expressions, allowing artists to explore intricate motifs and tell visual stories that were once time-consuming or cost-prohibitive to realize.