Direct to Fabric (DTF) transfer printing has transformed textile design with its ability to create intricate, personalized prints on various fabrics. Using a 'transfer sheet' for precise ink application, DTF allows designers to arrange multiple custom designs on a single sheet, enhancing flexibility and productivity while minimizing waste. Ideal for garments, accessories, and home decor, this method requires a balance of artistic skill and technical knowledge, with an emphasis on scale, color accuracy, and image resolution in graphic design software. Skilled artisans can craft personalized fabrics by combining diverse design elements, making DTF printing an accessible and exciting medium for bringing creative visions to life through fabric art. Efficient batching practices further optimize productivity while maintaining print quality.

Unleash your creativity with personalized DTF (Direct to Fabric) transfer sheets—a versatile printing method that combines multiple designs into a single, captivating layout. This guide explores the art of DTF, from understanding its unique advantages to designing eye-catching visuals. Learn how to masterfully arrange various designs on one sheet, optimize space, and enhance production efficiency. Discover the endless possibilities of custom DTF arrangements, perfect for both personal projects and commercial applications.

- Understanding DTF Transfer: A Versatile Printing Method

- Designing for DTF: Creating Compelling Visuals

- The Art of Arranging Multiple Designs

- Optimizing Layout: Tips for Efficient Space Utilization

- Production Considerations: Batching and Efficiency

- Exploring Creative Possibilities with Custom Arrangements

Understanding DTF Transfer: A Versatile Printing Method

The Direct to Fabric (DTF) transfer method has emerged as a versatile and efficient printing solution for creating personalized designs on various fabrics. This innovative technique allows designers and artisans to produce high-quality, detailed prints directly onto fabric sheets, offering immense creativity in their work. DTF involves a unique process where ink is transferred through a thin film or ‘transfer sheet’ onto the desired fabric, enabling precise and vibrant color reproduction.

With DTF Printing, multiple designs can be arranged and customized on a single transfer sheet, providing an unparalleled level of flexibility. This method is particularly advantageous for creating custom garments, accessories, or home decor items with intricate patterns and personalized messages. By combining different designs on one sheet, artisans can efficiently produce a diverse range of products while minimizing waste and maximizing productivity.

Designing for DTF: Creating Compelling Visuals

Designing for DTF (Direct to Fabric) transfer sheets involves creating compelling visuals that translate well onto various fabrics. This process requires a thoughtful balance between artistic expression and technical precision. With DTF Printing, designers must consider factors like scale, color accuracy, and image resolution to ensure the final prints meet expectations. High-quality images with sharp details are crucial for achieving crisp DTF transfers.

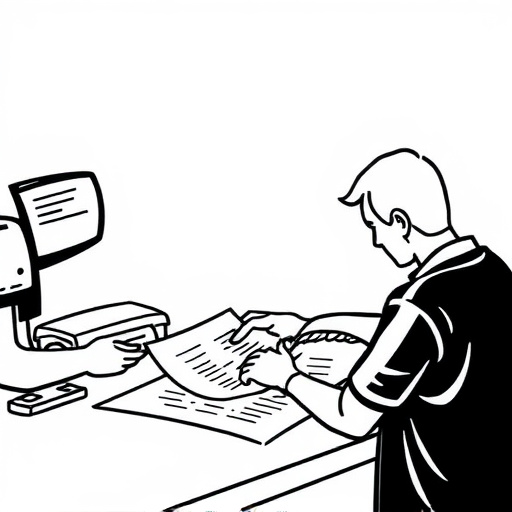

Using graphic design software, artists can arrange multiple designs on a single transfer sheet, allowing for personalized and unique fabric art. This technique is particularly appealing in the world of DTF as it enables creativity while maintaining efficiency. By optimizing layout and utilizing appropriate file formats, designers can produce eye-catching DTF prints that cater to diverse customer preferences.

The Art of Arranging Multiple Designs

The art of arranging multiple designs on a single transfer sheet is a creative process that allows for endless design possibilities with DTF (Direct to Fabric) printing. This technique involves carefully planning and organizing various motifs or patterns, ensuring they complement each other while maintaining visual harmony. Each design element must be considered in terms of size, color, and placement to achieve a balanced composition.

By skillfully combining different DTF transfer designs, artisans can create unique, personalized fabrics. This approach is particularly appealing for those seeking to craft custom garments, home decor items, or even accessories with intricate patterns. The versatility of DTF printing enables users to experiment with various layouts, making it an accessible and exciting method for designers and hobbyists alike to bring their creative visions to life through fabric art.

Optimizing Layout: Tips for Efficient Space Utilization

When arranging multiple designs on a single DTF transfer sheet, optimizing the layout is key to efficient space utilization. Start by considering the size and shape of each design element. Arrange smaller motifs around larger ones to create balance and prevent crowded areas. This strategic placement ensures every element gets adequate room while maximizing the overall design coverage.

Utilize whitespace wisely to avoid a cluttered look. Leave some negative space between designs, especially if they have intricate details. This provides a clean backdrop for each element, making them stand out individually and as part of a cohesive whole. Remember, an optimal layout not only enhances visual appeal but also simplifies the transfer process, leading to higher-quality DTF prints.

Production Considerations: Batching and Efficiency

When personalizing multiple designs on a single transfer sheet with DTF (Direct to Film) technology, efficient batching practices are key to maximizing productivity and minimizing waste. This involves carefully planning and organizing the design layout, ensuring that each element is optimized for placement while maintaining the desired level of detail and quality in each DTF print. By strategically arranging designs, you can reduce the number of cutting steps required, optimize material usage, and streamline the overall production process.

Batching also plays a crucial role in enhancing efficiency during the actual printing process. DTF transfer sheets require precise alignment and consistent application of pressure to achieve successful transfers. Batching similar or complementary designs together allows for more uniform handling, reducing the risk of human error and ensuring each print is of the highest quality. This meticulous approach not only boosts production speed but also contributes to consistent results, making it an essential consideration in the DTF printing process.

Exploring Creative Possibilities with Custom Arrangements

With the advent of DTF (Direct to Fabric) transfer technology, artists and designers now have an unparalleled opportunity to explore creative possibilities with custom arrangements on a single transfer sheet. DTF Printing allows for the seamless integration of multiple designs, enabling users to create intricate patterns, vibrant murals, or personalized textiles with ease. By combining various graphics, texts, and illustrations, one can craft unique pieces that reflect individual style and artistic vision.

This versatility opens doors to endless design options, from fashioning custom home decor items to producing limited-edition clothing lines. DTF Transfer sheets offer a flexible canvas where designers can experiment, merge concepts, or even reinterpret existing artworks. The process encourages playfulness, fostering an environment where creativity thrives and the only limit is one’s imagination.