DTF (Direct to Fabric) transfer sheets are versatile carriers for designs that can be printed and transferred onto various materials. This technology allows for precise control over placement and print quality, offering both professionals and hobbyists a high-quality, efficient way to customize fabric, wood, and metal with intricate patterns and stories. DTF Printing's ability to combine multiple unique designs on a single sheet has revolutionized fashion and home décor, enabling the creation of personalized, eye-catching pieces. However, achieving perfect DTG prints requires careful preparation, including using high-resolution artwork and fine-tuning printer settings for optimal results on different fabrics.

Unleash your creativity with personalized DTF (Direct to Fabric) transfer sheets—a game-changer for designers and crafters. This comprehensive guide explores the art of crafting intricate designs with multiple layouts on a single sheet. Learn how to seamlessly arrange diverse patterns, colors, and styles, transforming simple fabric into stunning masterpieces. Discover technical insights on printing, preparation, and the benefits of DTF transfers, from fashion to home decor. Master the technique for flawless, personalized prints that leave others in awe.

- Understanding DTF Transfer Sheets: A Comprehensive Guide

- The Art of Customization: Designing Multiple Layouts on a Single Sheet

- Unlocking Creative Potential: Arranging Different Designs Seamlessly

- Technical Insights: Printing and Preparation Processes for DTF Transfers

- Benefits and Applications: From Fashion to Home Decor

- Mastering the Technique: Tips for Achieving Flawless Personalized Prints

Understanding DTF Transfer Sheets: A Comprehensive Guide

Understanding DTF Transfer Sheets is key to unlocking endless design possibilities in the world of printing and crafting. DTF (Direct-To-Fabric) Transfer Sheets are thin, flexible sheets that act as a temporary carrier for your designs before they’re transferred onto various materials like fabric, wood, or metal. This innovative technology allows for precise control over the placement and quality of prints.

When you use a DTF Transfer Sheet, your design is first printed onto the sheet using specialized ink and equipment. The sheet acts as a stencil, allowing only the desired areas to accept the ink. Once the design is perfectly aligned, it’s then transferred onto the final medium through heat and pressure. This process ensures crisp lines, vibrant colors, and detailed prints—making DTF Printing a favorite among professionals and hobbyists alike for its versatility and high-quality results.

The Art of Customization: Designing Multiple Layouts on a Single Sheet

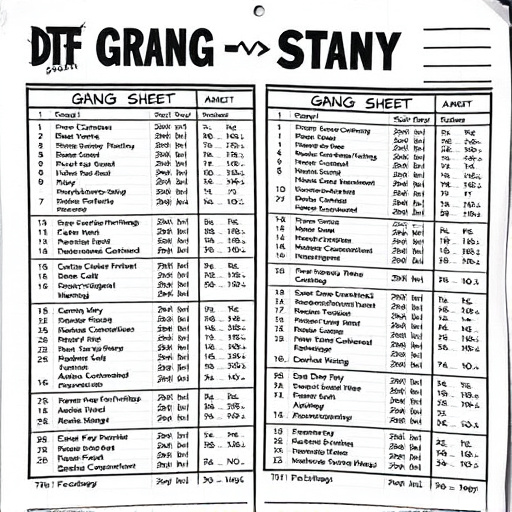

The art of customization in DTF (Direct-To-Fabric) transfer printing has opened up a world of creative possibilities for designers and artisans. One of the most innovative techniques is the ability to arrange multiple unique designs on a single transfer sheet, offering an efficient and versatile approach to fabric decoration. This method allows creators to tell complex stories or achieve intricate patterns with ease. By customizing layouts, artists can produce one sheet that becomes a symphony of design elements, each ready to be precisely applied to various fabric surfaces.

This technique is particularly beneficial for businesses and individuals looking to streamline their production process while maintaining high-quality results. With DTF printing, multiple prints or monograms can be arranged in specific configurations on a single transfer, eliminating the need for separate sheets for each design. This not only saves time but also reduces waste, making it an eco-friendly choice. The custom arrangement of designs enables a vast array of applications, from personalized apparel to decorative home textiles, where one sheet can cater to diverse customer preferences and requirements.

Unlocking Creative Potential: Arranging Different Designs Seamlessly

Unleashing your creative potential has never been easier with DTF (Direct to Fabric) transfer technology. By personalizing a single transfer sheet with multiple designs, artisans and creators can transform ordinary fabrics into captivating works of art. This innovative approach streamlines the design process, allowing for seamless integration of diverse patterns and illustrations onto various materials.

Imagine the possibilities: create unique clothing lines, customize home decor items, or even develop limited-edition accessories. With DTF Printing, arranging different designs becomes a delightful, hassle-free experience. You can effortlessly mix and match styles, colors, and themes, crafting arrangements that tell a story or convey a specific aesthetic. The versatility of DTF Transfer opens doors to endless creative expressions, empowering individuals to turn their visions into tangible, vibrant reality.

Technical Insights: Printing and Preparation Processes for DTF Transfers

The process of creating personalized arrangements with multiple designs on a single DTF (Direct to Fabric) transfer sheet involves intricate technical steps. DTF printing offers a unique approach to fabric customization, allowing for detailed and precise designs. The journey begins with preparing the digital artwork, ensuring it meets the specifications required for DTF printing. This includes proper resolution, color profiles, and file formats. Once the design is finalized, it’s printed onto a special transfer paper using specialized inkjet printers.

The printing process utilizes UV-curable inks that react to light, ensuring precise and vibrant DTG prints. After printing, the transfer sheet undergoes a curing stage where the ink hardens, making it ready for application onto various fabrics. This meticulous preparation ensures that each design element is accurately transferred, resulting in high-quality, personalized fabric designs.

Benefits and Applications: From Fashion to Home Decor

The personalized arrangement of multiple designs on a single transfer sheet, facilitated by DTF (Direct to Fabric) Transfer technology, offers a plethora of benefits and versatile applications across various industries. This innovative process allows for the creation of unique, custom-tailored prints that were once unimaginable with traditional methods. Designers can now seamlessly blend diverse patterns and motifs, crafting eye-catching compositions that truly stand out.

In the realm of fashion, DTF Printing empowers designers to create limited-edition garments adorned with intricate, multi-colored patterns. From bold graphic designs to delicate floral arrangements, clothing, accessories, and even footwear can be transformed into wearable art pieces. Similarly, in home décor, this technology is revolutionizing the way we adorn our spaces. Curtains, throw pillows, bed linens, and wall hangings can be customized with personalized prints, allowing homeowners to express their unique styles and create atmospheres that truly reflect their personalities.

Mastering the Technique: Tips for Achieving Flawless Personalized Prints

Mastering the art of personalized DTF (Direct to Fabric) transfer printing involves a combination of skill and precision. To achieve flawless results, start by preparing your design software carefully. Ensure your artwork is high-resolution and correctly scaled for the fabric size you intend to print on. Clean lines and crisp details are essential; any imperfections may be amplified when transferred onto the material.

Practice makes perfect. Experiment with various settings on your printer, especially temperature and pressure, as these significantly impact the quality of DTF prints. Use scrap sheets to test different combinations until you find the sweet spot for your specific fabric type. Remember, each material has unique characteristics that will affect how the ink adheres and sets, so fine-tuning your process is crucial for consistent, high-quality DTF prints.