Direct to Fabric (DTF) Transfer Sheets revolutionize textile printing by enabling designers to create personalized garments with intricate patterns on various fabrics using heat and pressure. These sheets allow for multi-design arrangements, streamlining processes, enhancing flexibility, and reducing waste. By optimizing layout designs using vector graphics software, creators can produce vibrant DTF prints tailored to individual preferences, from apparel to signage. DTF Printing's efficiency, cost-effectiveness, and detailed output make it a popular choice, as seen in successful implementations across industries.

Discover the art of maximizing creativity with personalized arrangements on a single DTF (Direct to Fabric) transfer sheet. This comprehensive guide explores the world of DTF technology, highlighting its unique advantages for custom design printing. From understanding the fundamentals of DTF sheets to crafting intricate multi-design layouts, we’ll walk you through the process. Learn tips and best practices for designing, efficient layout strategies, and real-world case studies showcasing the impact of personalized DTF transfers on various applications.

- Understanding DTF Transfer Sheets: A Comprehensive Overview

- The Benefits of Personalized Design Arrangements

- Designing for DTF Printing: Tips and Best Practices

- Creating Multi-Design Transfer Sheets: Step-by-Step Guide

- Maximizing Efficiency: Layout Strategies for DTF Prints

- Case Studies: Successful Implementation of Personalized DTF Transfers

Understanding DTF Transfer Sheets: A Comprehensive Overview

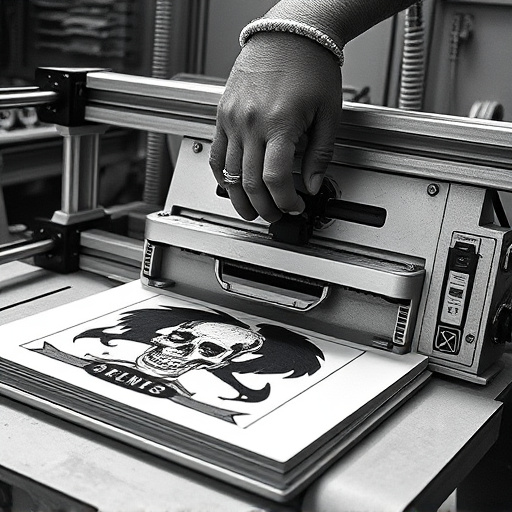

DTF (Direct to Fabric) Transfer Sheets are a revolutionary tool in the world of textile printing and design. This innovative technology allows for the precise application of intricate patterns, logos, or graphics directly onto various fabrics, enabling the creation of personalized and unique garments or accessories. A DTF transfer sheet is essentially a thin, flexible material that carries a reverse image of the desired design. The image is transferred to the fabric through heat and pressure, resulting in sharp, vibrant prints.

With a DTF Transfer Sheet, designers and printers can achieve complex arrangements by combining multiple designs on one sheet. This method streamlines the printing process, as it eliminates the need for individual sheets for each design variation. It offers immense flexibility, allowing artists to experiment with various compositions, color schemes, and layouts, all while maintaining high-quality prints. DTF Printing has gained popularity due to its efficiency, cost-effectiveness, and the ability to produce detailed, long-lasting DTF prints on a wide range of fabric types.

The Benefits of Personalized Design Arrangements

Personalized design arrangements on a single transfer sheet offer a multitude of advantages for creators and businesses alike. One of the key benefits is enhanced flexibility; artists can experiment with various patterns, colors, and layouts without the constraints of separate sheets. This allows for more creative freedom, enabling the production of unique, one-of-a-kind designs that stand out in the market.

Additionally, DTF (Direct to Fabric) transfer technology, when combined with personalized arrangements, streamlines the printing process. DTF Printing allows for precise and vibrant DTF prints, ensuring high-quality outcomes on a variety of materials. This efficiency not only saves time but also reduces waste, making it an eco-friendly option. With personalized designs, businesses can offer customized products, catering to individual customer preferences, and thus increasing customer satisfaction and loyalty.

Designing for DTF Printing: Tips and Best Practices

When designing for Direct to Fabric (DTF) printing, the process starts with creating a layout that can accommodate multiple designs on a single transfer sheet. This requires careful consideration of design placement and sizing to ensure optimal usage of space. Utilize software tools that support vector graphics, as these offer better scalability and quality for DTF transfers. Each design should be isolated and precisely positioned to avoid overlap or unnecessary gaps. Remember, the goal is to create a balanced arrangement that not only looks aesthetically pleasing but also allows for efficient cutting and application during the printing process.

Best practices involve keeping lines clean and avoiding intricate details within the fabric print area. Since DTF prints rely on heat transfer, ensure there’s adequate spacing between design elements to prevent smudging or fusing during the pressing stage. Incorporate registration marks or guidelines in your design for accurate positioning, especially when combining various elements. Testing on scrap material is crucial to verify that colors and line work translate well onto the fabric. Lastly, consider the intended use of the final product—whether it’s apparel, home decor, or something else—to tailor the design complexity accordingly.

Creating Multi-Design Transfer Sheets: Step-by-Step Guide

Creating Multi-Design Transfer Sheets involves a simple yet creative process that allows for endless design possibilities. Start by gathering your desired designs—these could be graphics, text, or patterns—and preparing them in a digital format suitable for DTF (Direct to Fabric) printing. Software like Adobe Illustrator or CorelDRAW is ideal for creating and editing vector-based designs.

Next, arrange your designs on a single transfer sheet, considering factors like size, orientation, and placement. Ensure each design fits within the cutout areas of the sheet without overlapping. Once satisfied with the arrangement, print your multi-design sheet using a DTF printer. The printed sheet will have individual designs separated by lines or borders, making it easy to cut out each design precisely. Now you’re ready to transfer your custom designs onto various fabrics for crafting, textile art, or apparel decoration.

Maximizing Efficiency: Layout Strategies for DTF Prints

In the realm of DTF (Direct to Film) printing, maximizing efficiency with a personalized arrangement of multiple designs on one transfer sheet is key. By strategically planning the layout of your DTF prints, you can optimize the use of space and reduce waste, ultimately saving time and resources. Consider dividing complex designs into smaller sections and placing them thoughtfully across the transfer sheet. This approach allows for seamless integration of diverse patterns or individual graphics without overlapping or leaving empty spaces.

Effective layout strategies involve aligning designs based on their characteristics—such as similar colors, motifs, or themes—to create a harmonious composition. Tools like graphic design software can assist in arranging and previewing these elements virtually, ensuring they meet your desired specifications before printing. A well-organized layout not only streamlines the production process but also enhances the overall aesthetics of the final printed products, whether for apparel, signage, or other applications.

Case Studies: Successful Implementation of Personalized DTF Transfers

In recent years, the application of DTF (Direct to Fabric) Transfers has seen significant advancements and successful implementations across various industries. Case studies from leading manufacturers and designers highlight the versatility and efficiency of this technology in creating personalized designs on a single transfer sheet. For instance, one study demonstrates how a small apparel brand utilized DTF Printing to produce unique, limited-edition t-shirts for their niche market. By digitally printing intricate patterns directly onto fabric, they achieved a high level of customization while maintaining cost-effectiveness.

Another notable example involves a large-scale event organizer who employed DTF Transfers to create personalized banners and backdrops for conferences and trade shows. This approach allowed them to offer tailored solutions to clients, ensuring each exhibit stood out. The success of these implementations lies in the ability to seamlessly integrate diverse design elements onto one transfer sheet, streamlining production processes and opening doors to innovative promotional and merchandising opportunities.