Direct to Film (DTF) printing technology disrupts custom design transfer sheets by streamlining processes, allowing intricate patterns and multiple designs on a single sheet. This innovative method enables high-quality personalized graphics for clothing, signage, and more. DTF offers unparalleled flexibility, swift trend adaptation, and cost-effectiveness, revolutionizing business and design. High-quality designs, durable materials, and robust adhesive backing enhance DTF's effectiveness. Embracing a "Don't Think Twice" (DTF) mindset encourages agile decision-making and innovation, while strategic vector graphic design tools ensure precise transfer of custom designs onto diverse materials. In supply chain management, "DTF" strategies streamline demand forecasting and rapid response mechanisms, emphasizing real-time data and adaptive planning for optimal resource allocation in today's fast-paced market.

Discover the art of maximizing creativity with DTF (Direct to Film) printing technology. This innovative process allows for the personalized arrangement of multiple designs on a single transfer sheet, opening doors to endless design possibilities. From enhancing fashion and apparel to transforming home decor, DTF offers unparalleled versatility. This article explores the technology behind DTF, its advantages, essential components for success, creative applications, and the diverse industries it benefits.

- Understanding DTF (Direct to Film) Printing Technology

- Advantages of Personalized Design Arrangements

- Components of a Successful Multi-Design Transfer Sheet

- Creative Ways to Utilize Multiple Designs on One Sheet

- Best Practices for Designing and Arranging Custom Transfers

- Applications and Industries Benefiting from DTF's Versatility

Understanding DTF (Direct to Film) Printing Technology

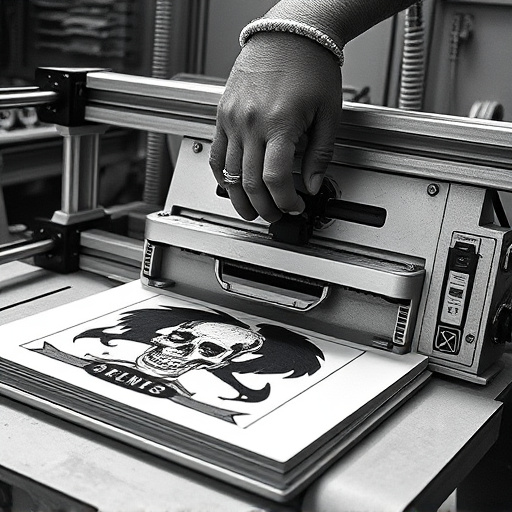

DTF, or Direct to Film, printing technology has revolutionized the way we approach custom design transfer sheets. This innovative method eliminates the need for intermediate steps, allowing designers to create intricate patterns and multiple designs on a single sheet with precision and efficiency. By directly applying ink to a film, DTF printing enables the production of personalized, high-quality graphics for various applications, such as clothing, signage, and decorative items.

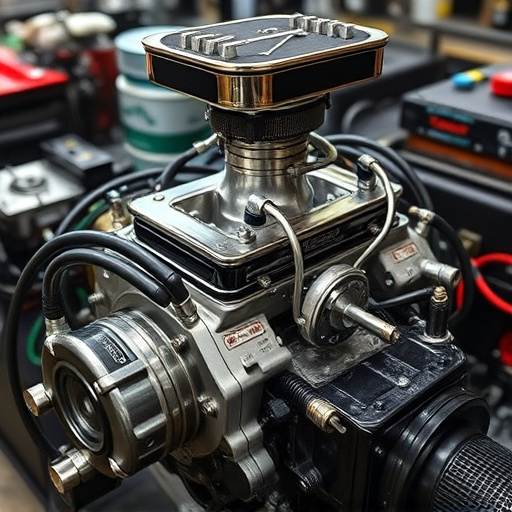

The process involves sophisticated machinery that precisely controls ink deposition, ensuring each design element is accurately transferred onto the desired substrate. This technology offers unparalleled flexibility, enabling users to experiment with different layouts, color schemes, and designs without compromising quality. DTF printing’s versatility has made it a game-changer in the industry, offering businesses and designers an efficient way to bring their creative visions to life.

Advantages of Personalized Design Arrangements

Personalized design arrangements offer a myriad of advantages, especially in today’s diverse and dynamic market. One of the key benefits is the ability to create unique and tailored products. By arranging multiple designs on a single transfer sheet, businesses can efficiently produce limited-edition items or customizable offerings that cater to individual customer preferences. This level of personalization allows brands to stand out and forge stronger connections with their audience.

Additionally, this approach streamlines production processes, as it consolidates various design elements onto one sheet, reducing the time and resources required for multiple runs. It also facilitates easier inventory management and cost-effectiveness, making it an attractive option for businesses aiming to enhance their product offerings while maintaining a lean operation. This method is particularly advantageous in the digital age, where trends evolve rapidly and consumer demands are ever-changing, allowing for swift adaptations in design production.

Components of a Successful Multi-Design Transfer Sheet

A successful multi-design transfer sheet, also known as a DTF (Direct To Fabric) sheet, relies on several key components to ensure optimal results. Firstly, the quality of the designs themselves is paramount. High-resolution, crisp graphics with precise lines and curves allow for detailed reproduction on various fabrics. These designs should be created or curated with fabric printing in mind, considering factors like color profiles and compatibility with different inks.

Secondly, the transfer sheet’s material plays a crucial role. A high-quality, durable paper or film ensures that the design adheres well to the fabric and withstand washing and wear over time. The surface of the transfer sheet should be smooth and free from impurities to facilitate easy application without smudging or misalignment. Additionally, the adhesive on the backing must be strong yet removable, allowing for precise placement and secure attachment during the printing process.

Creative Ways to Utilize Multiple Designs on One Sheet

Best Practices for Designing and Arranging Custom Transfers

When designing and arranging custom transfers, there are several best practices to ensure optimal results. First, utilize vector-based graphic design software like Adobe Illustrator or CorelDRAW. Vector graphics allow for precise scaling and sharp details, crucial for high-quality prints. Create individual designs for each unique element you plan to transfer, ensuring each has its own layer for easy manipulation.

Arranging the designs on a single transfer sheet requires strategic placement. Consider the final layout and size of your project; group complementary or matching designs together for seamless integration. Use guidelines and grid systems to align elements accurately. Save your file in DTF (Digital Transfer Format) to guarantee compatibility with printing software, enabling precise and efficient transfer of your custom design to various materials.

Applications and Industries Benefiting from DTF's Versatility